|

|

|

|

|

|

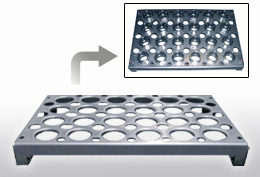

Line jig/palette

|

|

|

We produce the lining up palette which is most suitable for you!

|

|

|

|

|

|

We perform the automation design of washing / processing / assembling / the transportation process, production, execution, the maintenance.I will do the suggestion that not only the production of the palette but also an effect improves by abundant improvement experience and technology. |

|

|

|

|

|

|

|

|

|

|

|

The handling rationalization of the factory inside and outside!

|

|

|

Do'nt you use the different palette by each process?

You transship it and move it to work and do work? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If I think, I use the same palette by each process!

I commonize it and avoid waste of the work!

|

|

|

|

Our "lining up palette" solves the trouble of your company!

|

|

|

|

|

|

|

|

A part does'nt have the wound! |

|

|

| I make the palette which I matched with shape of a product (a part). Align it automatically and prevent a shock and do not damage a product! |

|

|

|

| There is not amount difference! |

|

| I can prevent a mistake and stockout of the amount by lining up! The amount check is simple, too! |

|

|

|

| Detergency improves! |

|

|

| If we make a palette for form of the washing machine, you can just wash it! In addition, the detergency by the posture lining up improves, too! |

|

|

|

|

|

Low cost! |

|

|

|

|

| Not an expensive manufacturing jig, I produce it by our metal plate processing. Large reduction in cost! And we can produce it from the design of the palette. Request please! |

|

| Lightweighting! |

|

|

In comparison with the manufacturing jig, the metal plate processing jig is lightweight!

Because it is complete special order production, I can cope with the careful hope of your company. |

|

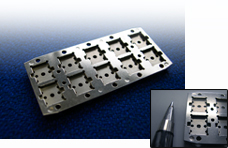

| Highly precise processing! |

|

|

| We realize highly precise processing on the heels of manufacturing! It can do loading by the robot. |

|

|

|

|

We innovate expensive cutting processing jig with precise sheet metal processing!

|

|

|

|

|

Material

|

・Stainless steel

(SUS430,SUS304,SUS316、Others)

・Titanium

・Aluminum |

|

production

|

・Tray ・Palette ・Lineup jig for automatic machine

・Jig for the conveyance ・Implementation jig ・Heat treatment Jig

・Cementation jig ・Heat dull jig ・Drying jig ・Basket for heatproof

・To heatproof nature an excellent High nickel material/career etc.

※Piling up it special order size, special specification, steps it is possible a production in accordance with the request! |

|

|

|

|

|

|

|

|

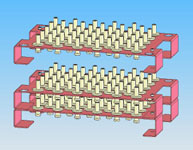

【Line jig】 |

|

|

|

Wounds of parts are prevented, and the line jig for transportation that improves the effect of the automation and the labor saving.

Size: 350×210×30 (mm)

|

|

|

|

|

|

The insertion hole is possibility even that narrows down to the flange!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 【A part delivery resin plate】 |

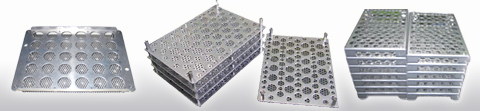

【Accumulation transportation & washing palette】 |

|

|

This is a lining up plate to deliver a molded article.This uses a resin board to prevent a wound transporting.In comparison with the machine cut product, it is low cost.

Size: 230×300×t6 (mm) |

|

|

|

|

This is the article that precision is important.I improved conventional machine cutting for metal plate processing and realized lightweighting and low cost without losing precision.By special hole shape, it has entrance performance same as a net basket! Strength more largely increased.

Size:150×150×150(mm)

Material:SUS304 (Ten steps of stacks.)

Punching processing / Circle stick reinforcement |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

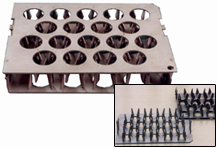

| 【Line palette】 |

|

|

|

| 【Removal jig】 |

|

|

The directions of parts do not change into the vibration under transportation because the hole can be processed according to the inserted part shape either.

Size: 225×240×30 (mm) |

|

|

|

These products pile up the palette which displayed parts, and it is a jig to transfer it in a plastic pail with the cover.It is effective for prevention of dirt at the time of each process and movement between factories. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 【Chip career】 |

【Optic part jig】 |

|

|

For transportation of crystal pendulum. It inserted by etching processing ⇒ sheet metal processing and low-cost was achieved easily.

Size: 30×60×2.5 (mm) |

|

|

It is Cleaning jig of an optic part.

Inserting the optic part (lens etc.) from top and bottom it fixes it.

Even precise jig for possibility optic part coating is producing in lens fixation department even Teflon material use, or coating of wound prevention. |

|

|

|

|

|

|

|

|

|

| 【Line career】 |

|

|

|

Making parts exhausted by an automatic machine line up can facilitate transportation to the next process.

small parts are made to be done in the slide because the processing accuracy and finish are good and it is smooth to do the insertion exhaust.

Size: 60×530×20 (mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 【Automatic brazing jig】 |

【Conveyance Palette】 |

|

|

This product stands in line with a part, and it is brazing and a jig to transport.It is the product which prevented transformation by many overheat.Therefore we improved processing shape.By this, you can use it for a long term and have lightweighting & low cost!

Size: 300×300 (mm)

Material:Stainless steel |

|

|

This product stands in line with a turning processing part, and it is a palette to transport it.You pile this up, and efficiency of the transportation improves. |

|

|

|

|

|

The conveyance of jig/palette is facilitated!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|