Products

Product Manufacturing

We custom design products according to customer requirements. We process practical products using the latest design and processing equipment and advanced production systems. We provide systematic proposals from design and prototyping to mass production.

Alignment jigs and pallets

We design, manufacture, install, and maintain automation for cleaning, processing, assembly, and transfer processes.

With our extensive experience in on-site improvements and technical capabilities, we offer proposals that show results, not just the manufacture of baskets, pallets, and jigs.

Our “Alignment Jigs and Pallets” will solve your problems!

Necessity of Alignment

◆ Preventing scratches on parts

By making pallets that match the shape of products(parts), they can be automatically aligned.

This prevents shocks and scratches on the products during transportation to each process and processing.

◆ Prevent missing items

Alignment naturally prevents errors in the number of items and missing items!

Easy to check the number of items!

◆ Improved cleaning effect!

If the pallets are shaped to fit the washing machine, they can be washed as they are!

The cleaning effect is also improved by posture alignment!

From machining to sheet metal processing

◆ Realization of low cost!

Instead of expensive machined jigs, we use our precision sheet metal technology to manufacture sheet metal products.

Greatly reduced costs!

Also, our pallets can be manufactured from the design stage. Please contact us for consultation!

◆Achieve weight reduction!

Compared to machined jigs, sheet metal jigs are expected to be lighter!

Since the jigs is completely custom-made, it can be adapted to your company’s detailed requirements.

◆Realize high-precision processing!

High precision processing id realized, close to that of machining, and loading by robot is possible.

Trays, pallets, alignment jigs for automatic machines, transport jigs, mounting jigs.

We innovate expensive cutting jigs with precision sheet metal processing!

| Material | ・Stainless steel (SUS430, SUS304, SUS316, etc.) ・Titanium ・Aluminum ・Resin(Teflon, ABS, vinyl chloride, nylon, PEEK resin, etc.) |

|---|---|

| Production | ・Tray ・Pallets ・Alignment jigs for automatic machines ・Conveyance jig ・Mounting jig ・Jig for heat treatment ・Carburizing jig ・Hot annealing jig ・Drying jig ・Brazing jig ・Heat treatment jig ・Carriers, etc. ・Pallets for delivery of parts(transported in an aligned state from upstream processes or subcontractors) ※Custom sizes, special specifications, and stacking are available upon request! |

Production Examples

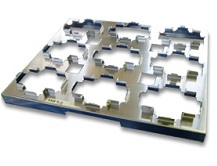

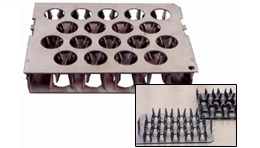

■ Heat treatment pallet for electronic parts(Large)

Material: SUS304

This is a product bent by integral molding without joining separate parts.

High processing accuracy was required for the pocket where electronic parts are inserted.

Light weight, high precision and low cost are realized.

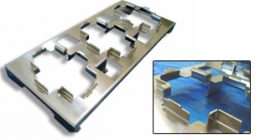

■ Alignment pallet for heat treatment of electronic parts(Small)

Material: SUS304

The integrated molding and bending process eliminates extra parts and improves the efficiency of the treated products by improving the heat circulation in the furnace.

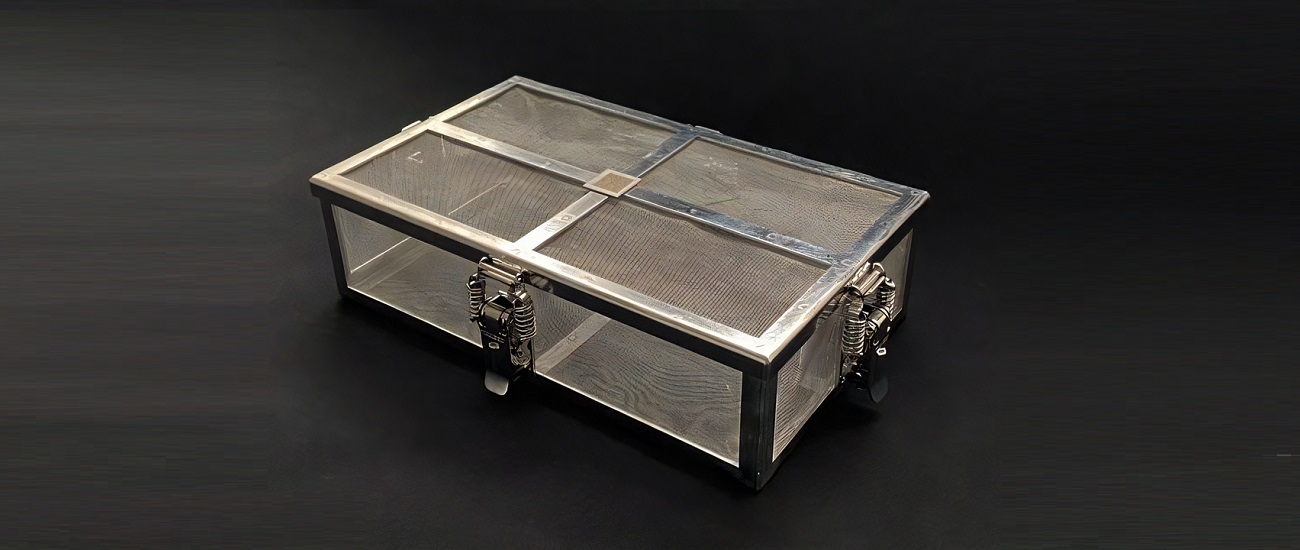

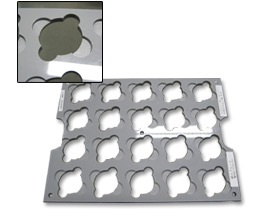

■ Cleaning palette for optical components

Material: SUS304

The complex shape of the product is bent in one piece.

Optical parts are mounted on the main body and fixed with the lid for cleaning.

Two types of components with different dimensions can be aligned.

■ Jig for alignment, cleaning, and transportation

This is an alignment jig for conveyance that prevents scratches on parts and increases the effectiveness of automation and labor saving.

We will design and manufacture according to the shape of your products.

■ Resin plate for parts delivery

This is an alignment plate for delivering molded products.

The resin plate is used to prevent scratches during transportation.

Since it is processed by sheet metal processing technology, the cost is lower that that of machined products.

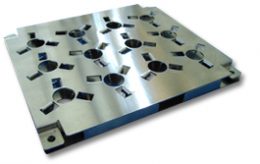

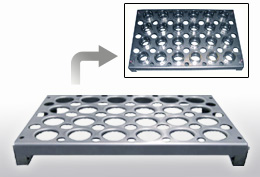

■ Stackable transport and washing pallets

Material: SUS304, 10 layers

Punching process, round bar reinforcement

Since high precision is required, the conventional machine cutting process has been improved to sheet metal processing to achieve weight reduction and cost reduction.

The special hole shape has significantly increased the strength while maintain the same drainage performance as the net basket.

■ Alignment palette

This is a jig with holes machined to match the shape pf the parts to be inserted, so that the orientation of the parts does not change during transportation.

The hole shape can be freely processes.

■ Jig for stacking and transporting

This is a jig for stacking pallets of parts and transporting them with a plastic bucket with a lid.

It is effective in preventing contamination when transporting between processes and factories.

■ Chip carrier

Etching process ⇒Sheet metal processing realizes easy insertion and low cost product.

■ Optical component jig

We also manufacture precision jigs for optical component coating.

■ Alignment carrier

This is a jig that aligns parts discharged from an automatic machine to facilitate transfer to the next process.

Due to its good processing accuracy and finish, it is smooth to slide small parts for insertion and discharge.

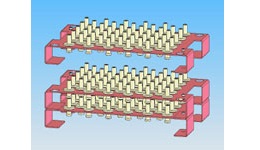

■ Jig for automatic brazing

Material: Stainless steel

This is a jig for arranging, brazing and transporting parts.

Since it is required to prevent deformation due to repeated overheating, we have improved the processing shape to extend the life of the jig, while reducing weight and cost.

■ Pallet for stacked transportation

The pallets can be stacked in several layers to improve the efficiency of transportation.